Using Kentucky’s Tiled Base Maps in MotionX-GPS & Gaia GPS apps

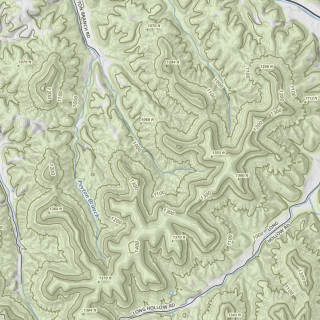

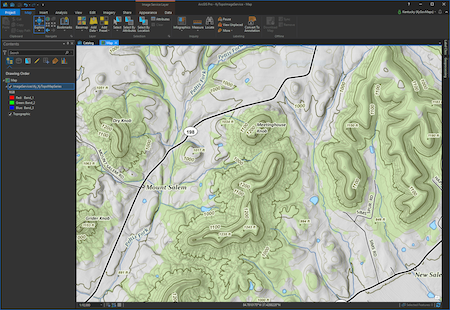

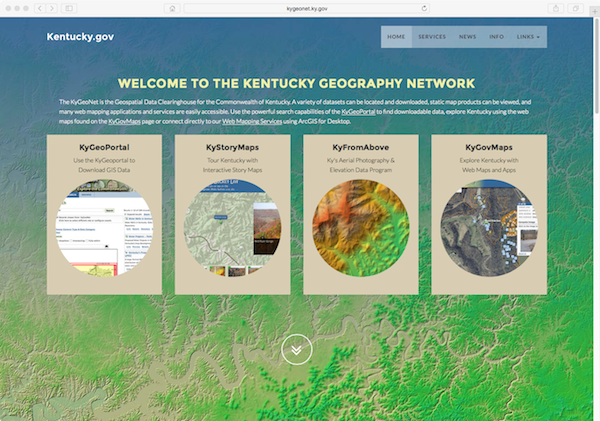

This post isn’t aimed at any particular group, but I suspect that folks who are interested in things like the Kentucky Adventure Tour (KAT) will find it to be useful. Navigating the KAT requires...